Manufactured using a unique production process. Highest grade, super fine tungsten powder is blended with nickel, iron, and zinc, compressed and then sintered at over 3150°C. The resulting billets are then precision machined into radical barrel profiles. Every barrel is subjected to a double exposure hot pressed Vapour Deposition Process, which creates an ultra durable, non slip coating

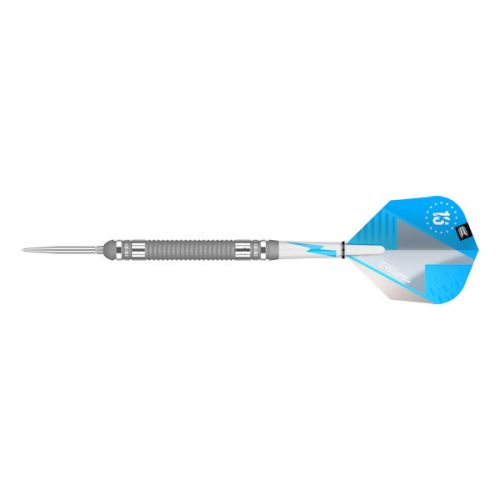

Features:

- Double thermal Vapour Deposition Exposure = ultra durable, non slip coating. Reverse cut groove barrels, Supergrip shafts

- Change the gram weight in drop box to view different barrel design